Shomurod Jamolov and Sherzod Bazarov from Textile Technologies & Services LLC (TTS), Mayer & Cie.’s representation in Usbekiztan, spent a week at Mayer & Cie. headquarters in Albstadt, Germany for an in-depth training of circular knitting machines and applications. They gained an overview on the entire production process of circular knitting machines and were also given an insight into patterns and designs.

Thank you, Shomurod, for talking to us. Can you please introduce yourself, your job and the company you work for?

I have worked with Textile Technologies & Services LLC for more than six years. We are based in the country’s capital, in Tashkent. In total, we are a team of around ten people. In the sales team, it’s Anna Tsoy, the director, and me. I’m deputy director of the company. We are supported by Daria, our Office Manager and Dana, our Project Manager. In Uzbekistan, companies are required to keep a wide range of official documentations and certificates; this is what a Project Manager looks after.

Our service team consists of three engineers. Sherzod, my colleague who travelled with me this week, is one of them. They are all very experienced and trained on Mayer & Cie. machines. We are happy to have such a good set-up in the service department.

How long have you been working in the textiles industry?

I’ve been in the textile industry for only six years, since I stared with TTS. I’m not a “native” to the business, my home turf is economics. That’s why I do sales (laughs).

When was the first time you got in touch with Mayer & Cie.? Do you remember the occasion?

It’s my first time at Mayer & Cie. headquarters in Albstadt. In fact, I only got to know Mayer & Cie. when I started at TTS. This is because of my different background. In the textile industry in Uzbekistan, Mayer & Cie. is well known and has a very good reputation as a premium circular knitting machine builder.

You’ve been at Mayer & Cie. for a week for training. What did you learn?

The training was very good. We’ve become familiar with the framing process, cam process, pre-assembly and final assembly. We virtually looked inside the circular knitting machines. We learned how to adjust machines. We got information on producing specific patterns. It feels like we learnt pretty much everything you can possibly know about circular knitting machines.

We were very impressed by the size of the company. The people at Mayer & Cie. are very nice. They have been extremely helpful, answering all our questions and explaining things well.

What were this week’s highlights?

I was fascinated by the company’s vertical integration. We didn’t know that Mayer & Cie. is handling whole production process, and hardly any no sub-suppliers. We saw that most parts are made here.

Witnessing a machine’s assembly was a real eye-opener. We weren’t aware how much fine mechanics is involved, how much attention to detail required. Adjusting a machine is precision at its best.

We now know where the quality comes from.

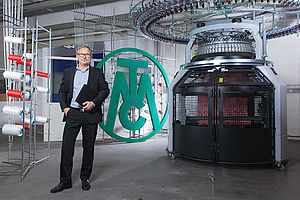

Timo Schramm with the visitors from Uzbekistan.

ADRESSE

Mayer & Cie. GmbH & Co. KG

Emil-Mayer-Strasse 10

72461 ALBSTADT

GERMANY

Mailing adress:

P.O Box 201580

72438 ALBSTADT

GERMANY

phone: +49 (0)7432 700-0

fax: +49 (0)7432 700-362

info(at)Mayercie.com

| © Mayer & Cie. | 2023 |