SF4-3.2 III

The SF4-3.2 III is the perfect choice when it comes to lightweight and elastic 3-thread fleece fabrics. They feature perfect plating results. Plus there are hardly any limits to the fleece thread’s thickness when working with the SF4-3.2 III. This is due to the fleece thread collecting the binding thread. In contrast to common procedure, the fleece thread is not positioned in the needle hook.

RELANIT 3.2 HS

The Relanit 3.2 HS knits all single jersey structures reliably with up to four needle tracks, for example piqué and double piqué, structured single jersey and two-thread fleece.

Thanks to the extremely reliable yarn supply the machine ensures the highest level of plating and process reliability. That makes it easy and convenient to operate. It also delivers all the tried and tested advantages of relative technology, such as a significantly lower energy consumption.

OVJA 2.4 EM

Let‘s be straightforward about the OVJA 2.4 EM: A highly productive double-knit jacquard machine with electronic needle selection in the cylinder. Plus double-layer fabric with lay-in thread. And all combined with a remarkable, reliable productivity.

The OVJA 2.4 EM features a newly developed yarn feeding system. Thanks to this component, the yarn feeds accurately both into the cylinder and into the dial tube. This helps to make drop stitches a very rare occurrence. Furthermore, the OVJA 2.4 EM‘s needle guidance is exceptionally gentle. Especially in relation to the machine‘s high productivity, wear and tear of the needles is unusually low.

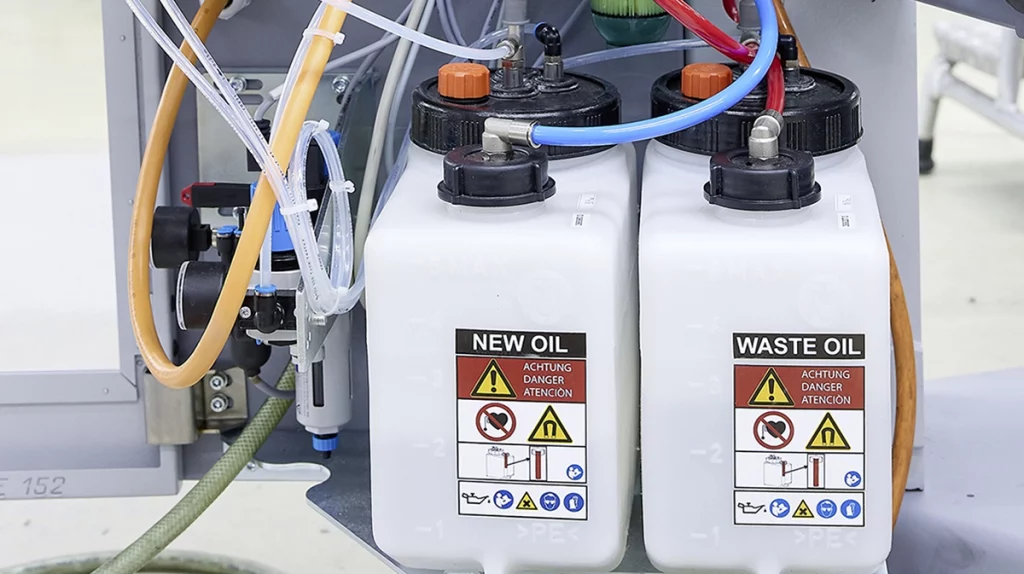

SENSO BLUE RS

Reduce needle oil consumption by up to 50 percent.

Senso Blue RS is Mayer & Cie.‘s machine-integrated lubrication and needle oil recycling system. Oil is applied optimally in terms of quantity and area. Used oil is collected, filtered three times and returned to the system.

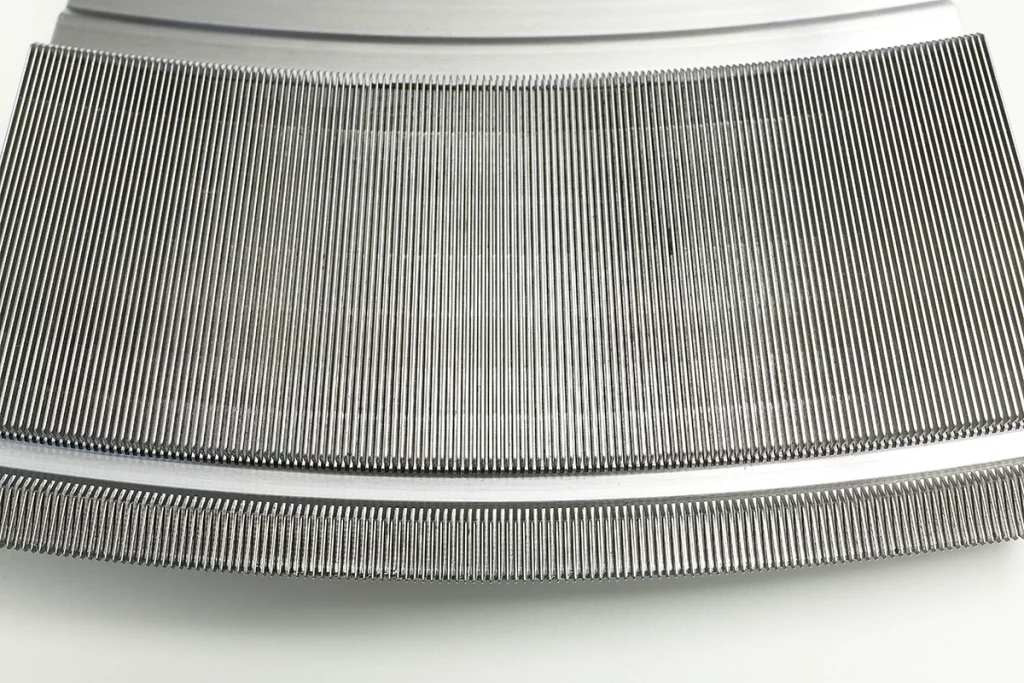

LASER-BASED NEEDLE BED TEMPERING

Rely on a longer service life thanks to new production process.

We are a leader in the circular knitting world. We set standards in developing new approaches and processes. The latest example is our new laser-based process for hardening the needle bed. Thereby, we can ensure a consistent hardness over the entire circumference of the needle bed.

KNITHAWK

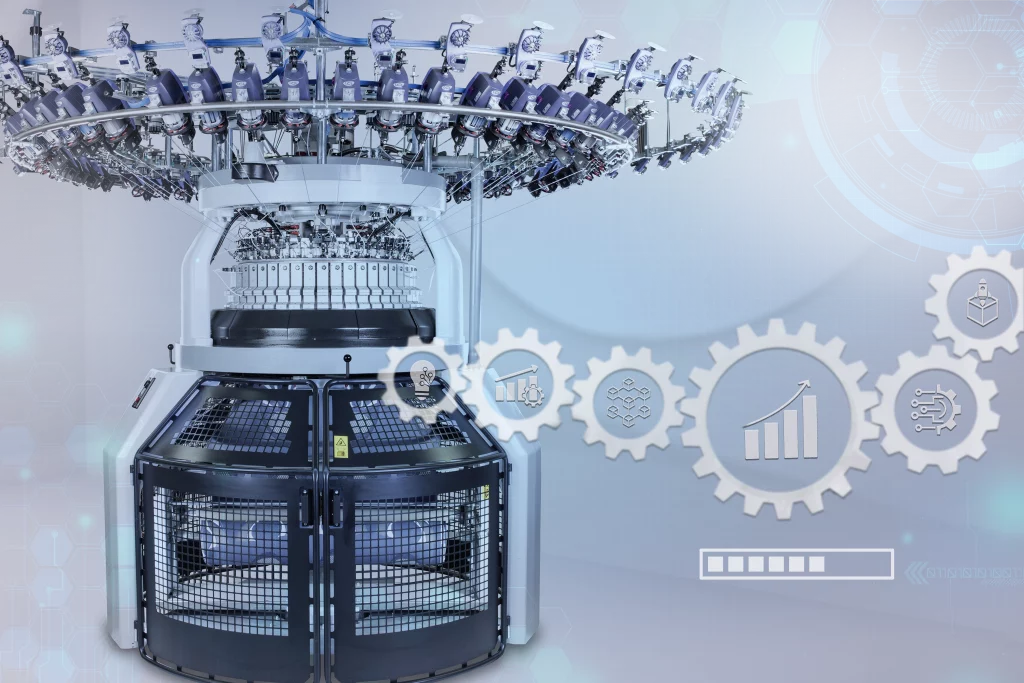

KNITLINK

Digital Knitting Solutions

The knitlink platform records the operating data of your Mayer & Cie. circular knitting machine(s) and visualises it. On a personalised dashboard, you can view the results clearly presented for all machines and, using the machine view, for the machine selected. In addition, knitlink provides a web shop for machine components and upgrade kits and opportunities for remote support and easier collaboration over long distances. Further functions will gradually be added.

Keeping an overview.

At a glance, my.monitoring provides you with all the operating data of one of our machines. Individual aspects can also be viewed in detail – from the machine’s status via running times and downtimes to recurring alarms and efficiency by the hour, the day or the week.

Always staying within reach.

With my.service you (and people you specify) can access your Mayer & Cie. machines at any time from anywhere in the world. In other words, competent support is available remotely and never more than a few clicks away.

Shopping without closing times.

With my.shop you can order components and upgrade kits for your Mayer & Cie. machine whenever and from wherever you want.

Using registered machines, the web shop will quickly provide you with accurate results.

MY.LOYALTYCLUB

Profit from up to 10 percent discount for upgrade kits, machine components and consumables. Member status depends on the customer‘s annual purchase volume of upgrade kits, machine components and consumables.

MY.SHOP

Find the right parts fast. Circular knitting machines from Mayer & Cie. are known for quality and performance over a long machine life. This requires the right spare and wear parts, guaranteed to be compatible and quickly to hand. These are available in our webshop.

UPGRADE KITS

Benefit from our technical progress in existing machines. To benefit from our ingenuity and experience you do not always need to have the latest Mayer & Cie. model. That is just as it should be. After all, the majority of your machines have their well-deserved place in your machine park.

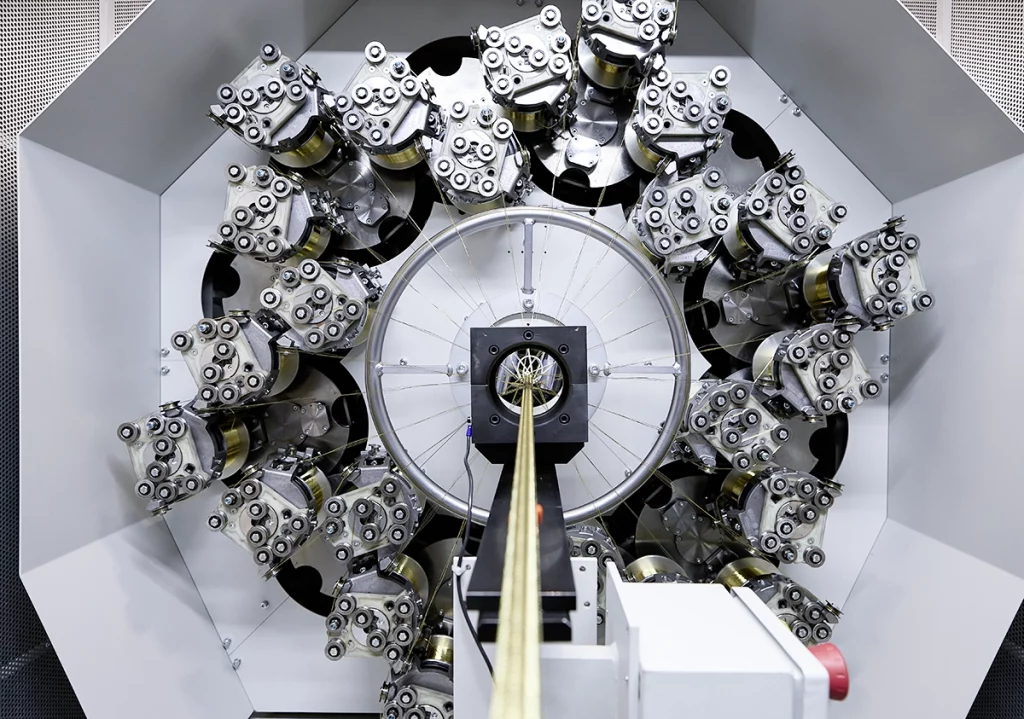

BRAIDERS FROM MAYER & CIE.

The high-pressure hoses you manufacture on our machines withstand every element.

They have to; few areas of modern life function without them. In industrial production, on construction sites or in agriculture they are ever-present. And when working conditions become inhospitable, such as at sea or underground, the safety of man and machine can depend on a reinforced high-pressure hose.