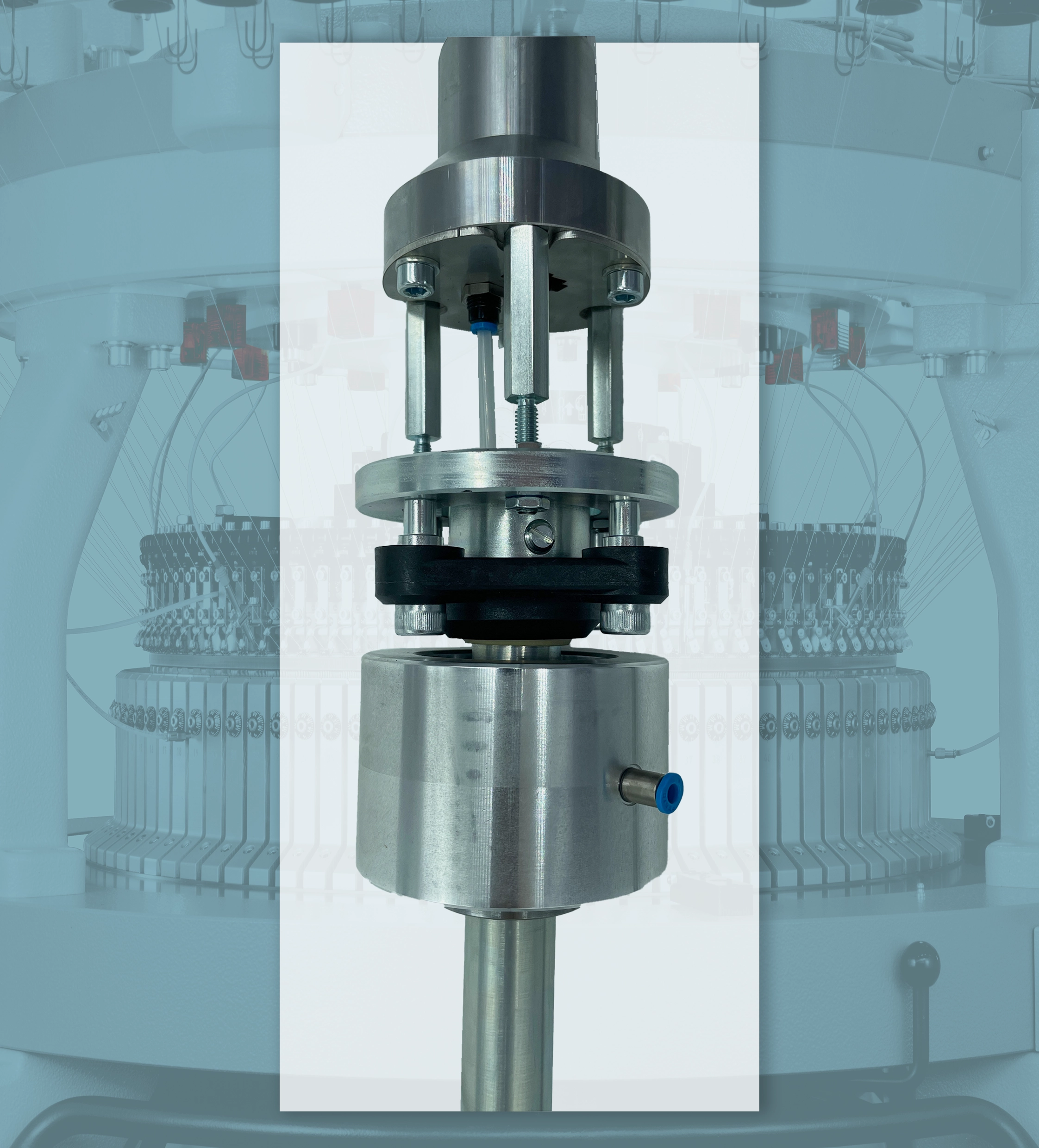

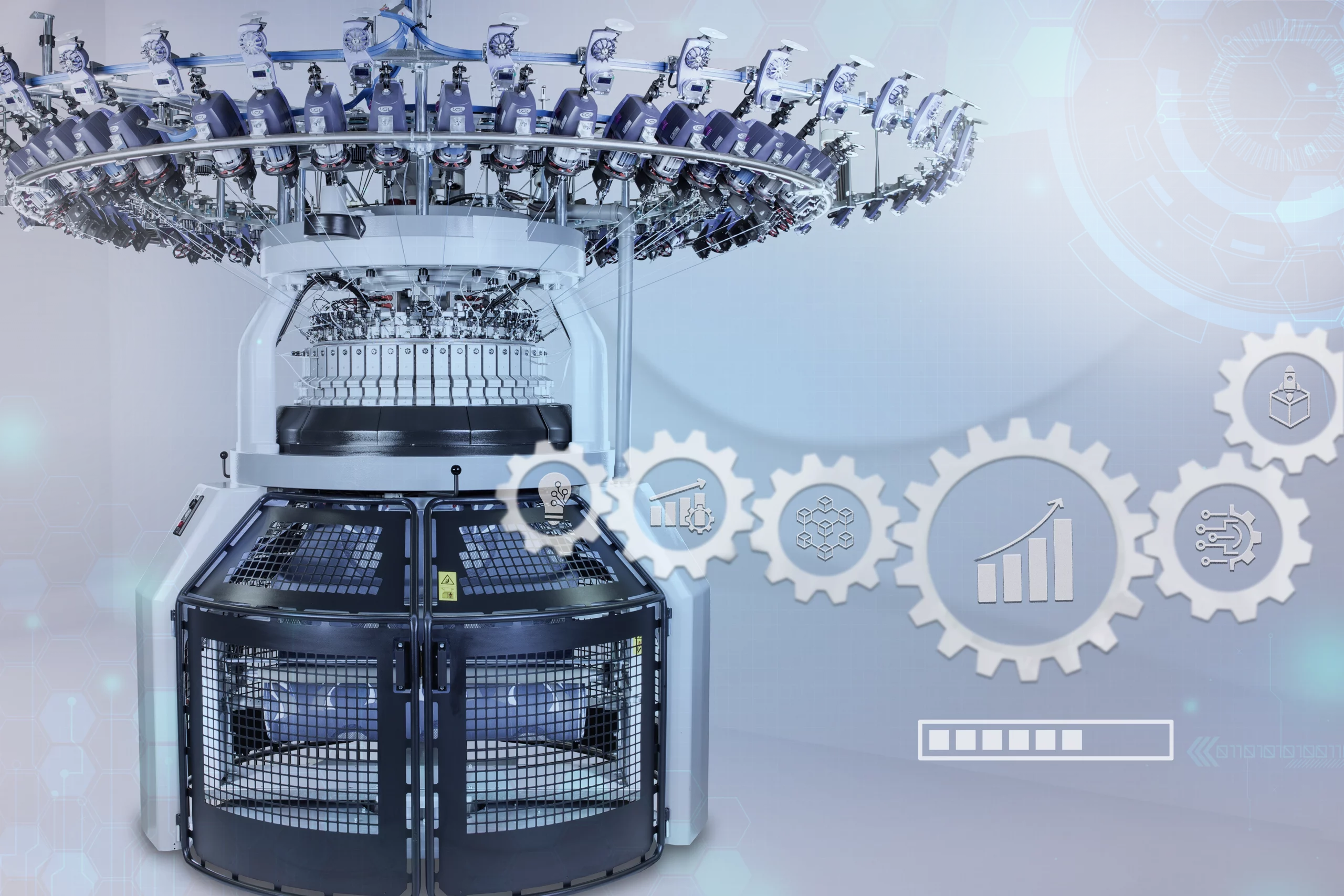

Senso Blue RS – machine-integrated lubrication and needle oil recycling system

Existing machines can be equipped with Senso Blue RS, Mayer & Cie.‘s machine-integrated lubrication and needle oil recycling system.

Existing machines can be equipped with Senso Blue RS, Mayer & Cie.‘s machine-integrated lubrication and needle oil recycling system.

The entire range of patterns in one piece of software – for all electronic Mayer & Cie. circular knitting machines

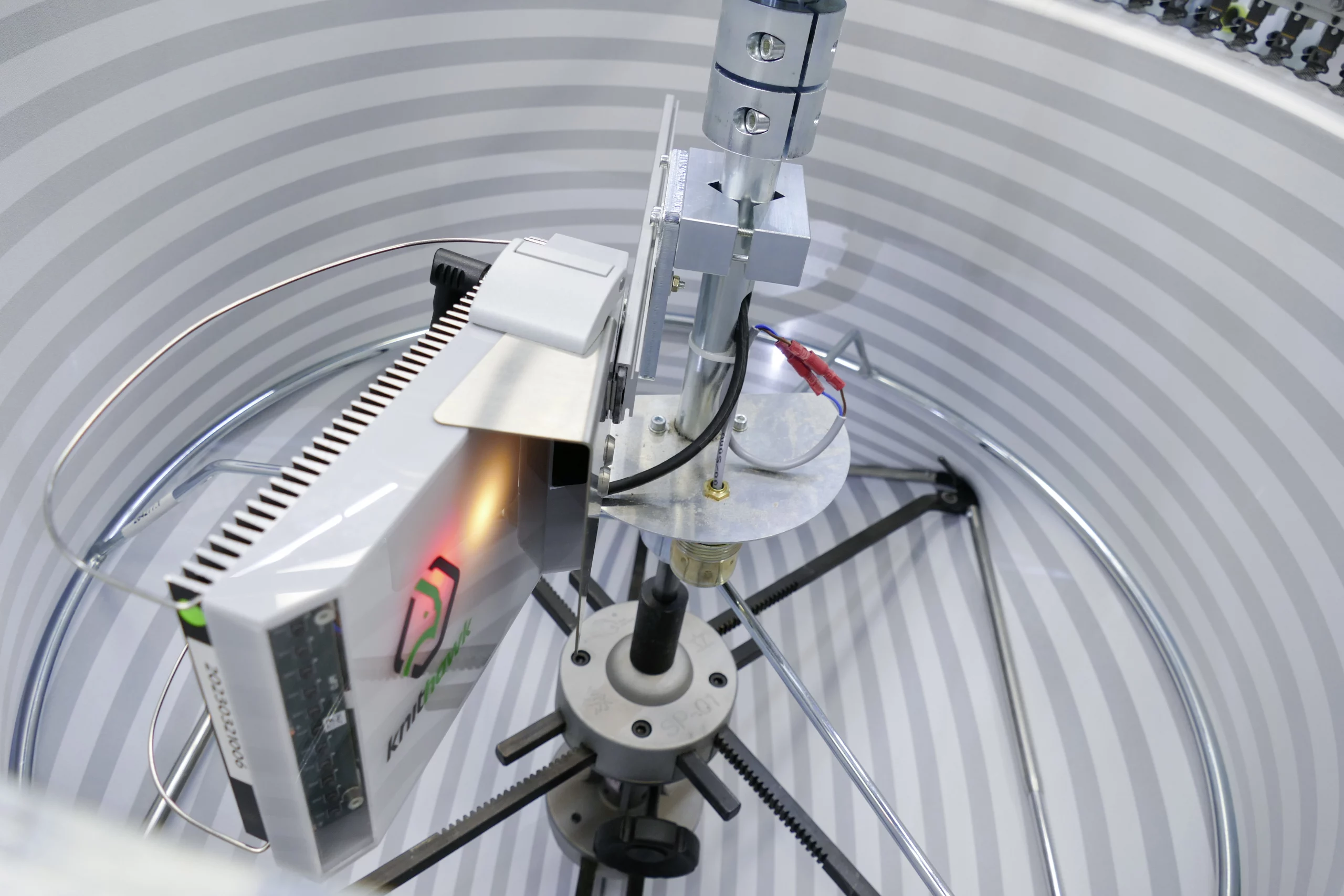

Mayer & Cie. knithawk identifies imperfections such as spot defects, vertical defects, horizontal defects and

defects in elastomeric plating in single jersey structures.

Increase machine output for elastomeric plating knitted fabrics by up to 20 percent. Compatible with the following machine types: S4-3.2 II

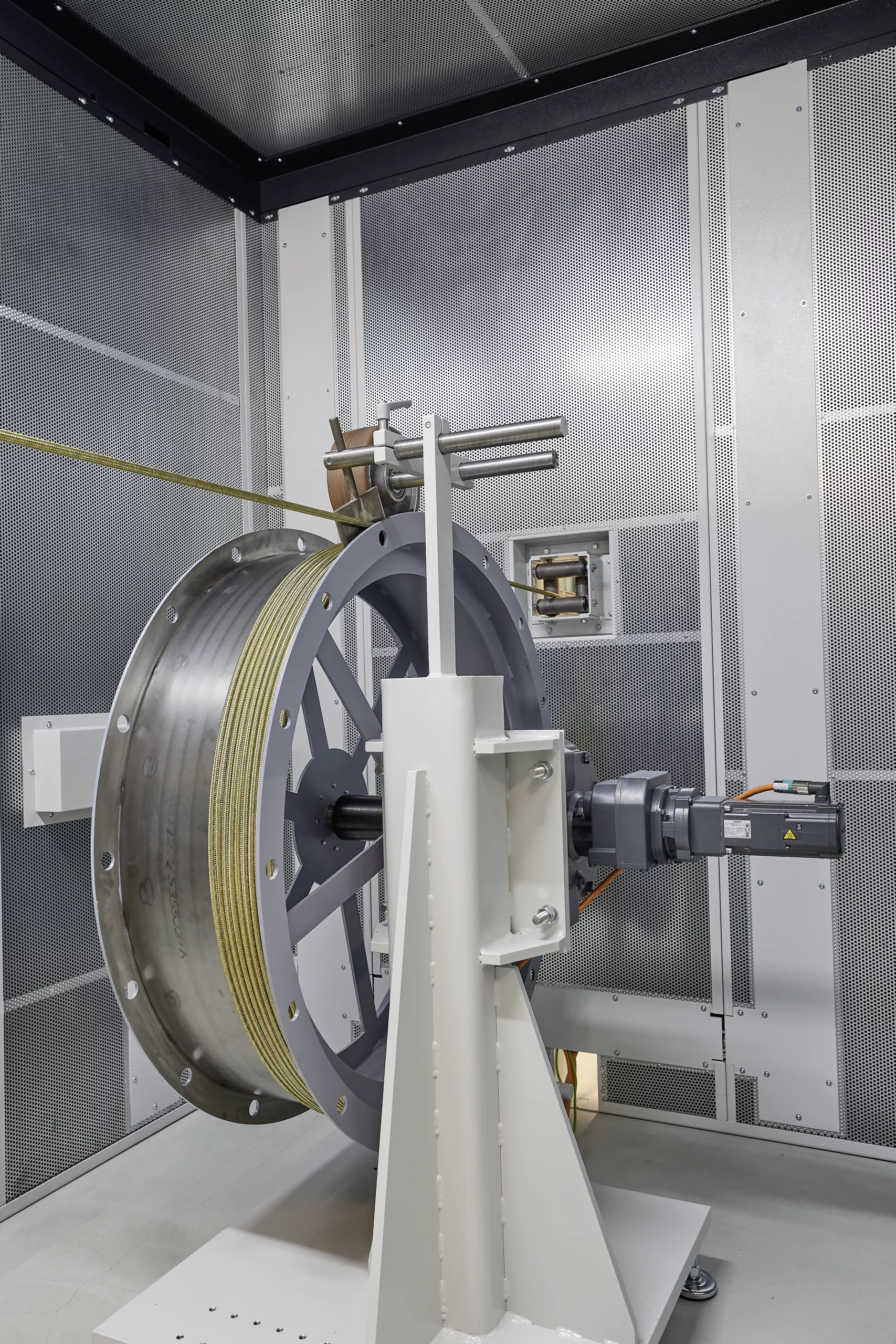

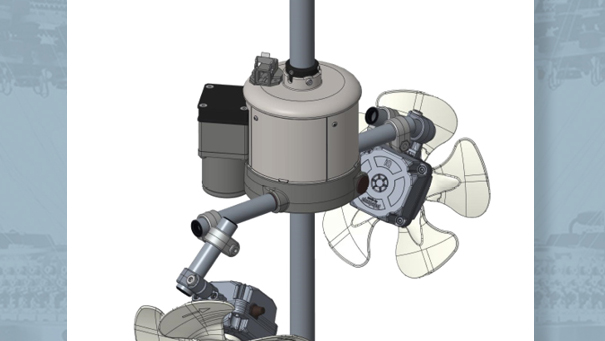

The friction wheel is an alternative take-off unit in the braiding process

With the SpeedBooster Upgrade Kit, users can improve their existing braiding machines efficiency. This means increasing their value or maintaining it in the long term

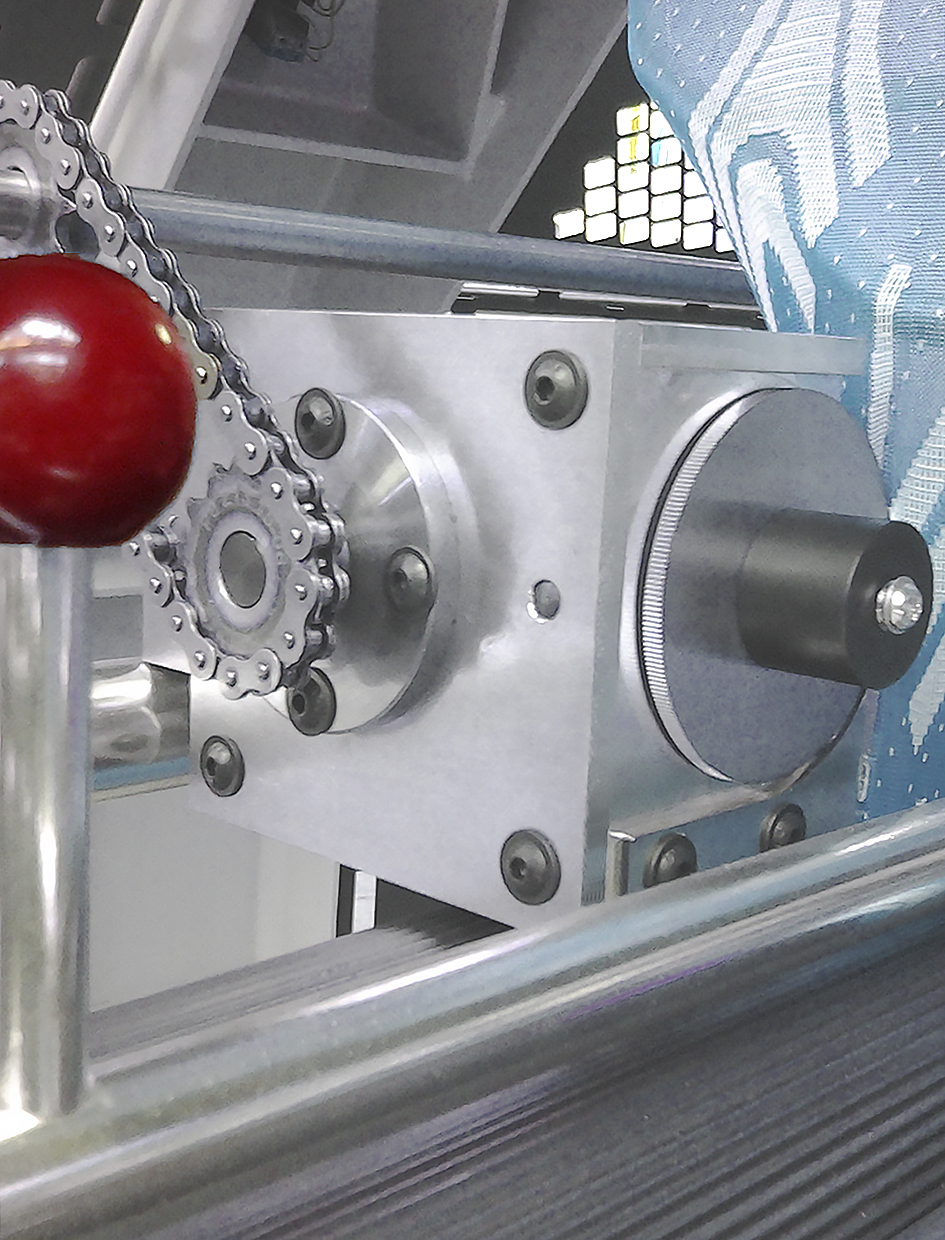

The machine control upgrade kit replaces the existing shaft drive system by the current system, which uses servomotors. It is compatible with all MR 11and MR 15 models with an

The machine control upgrade kit replaces the existing shaft drive system by the current system, which uses servomotors. It is compatible with all MR 11and MR 15 models with an

Automatic cutting and opening of the fabric tube – while knitting.

Compact and space-saving design right underneath the spreader..

More robust knitting performance-

Flexibility is the key to the knitting machine‘s extra sturdyness

Increase your production by up to 20 percent depending on desired pattern and yarn!‘’

knithawk is a tool for optical defect detection. It is positioned directly behind the knitting point and consists of a camera unit that „scans“ the knitted fabric using infrared light. If knithawk detects a serious or recurring defect, the machine is stopped automatically.

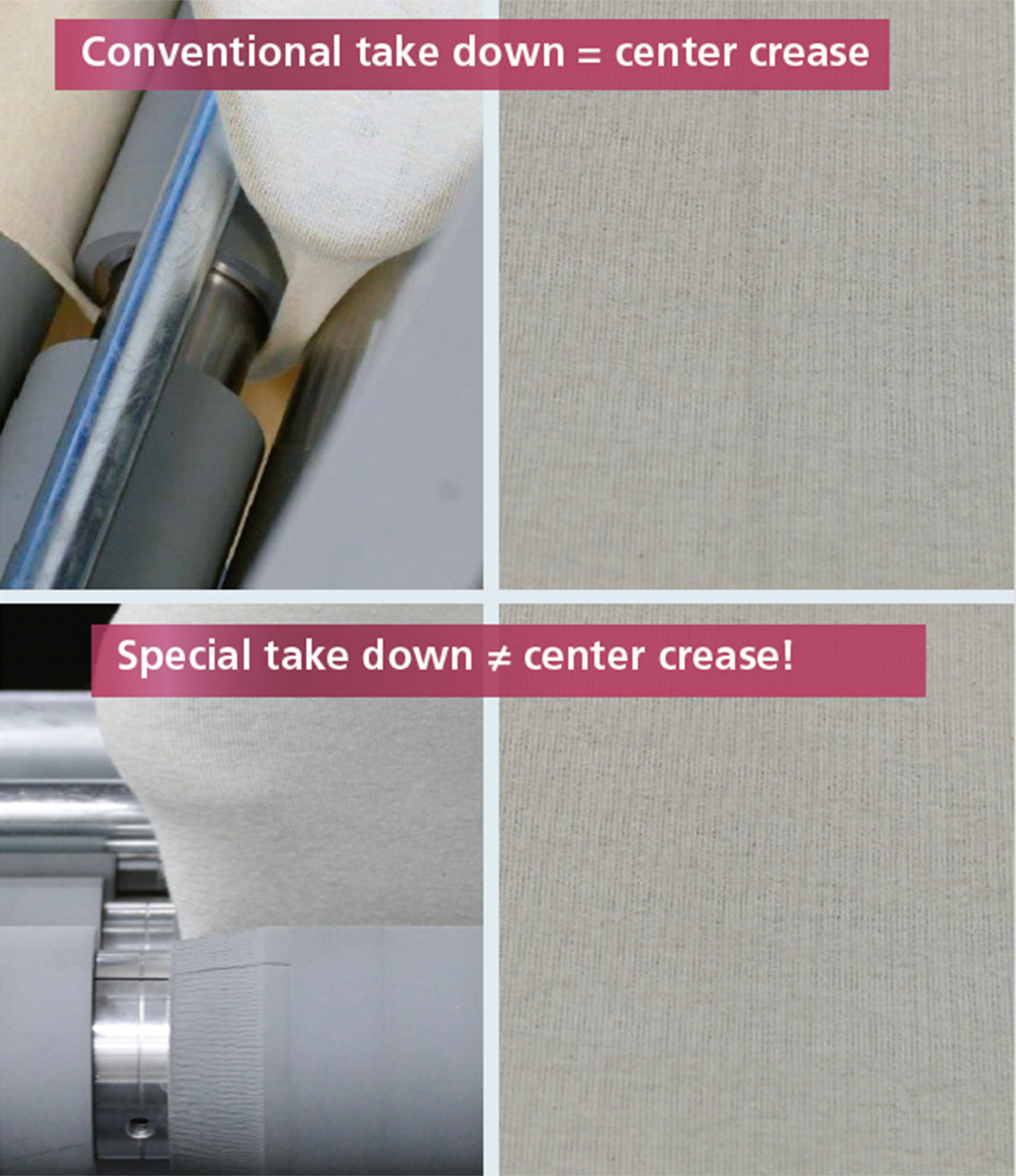

For best results combine the special take down with our plaiting device (see reverse).

Horizontal lay-in yarn guide

Improved holding down function for less repositioning of horizontal yarn guide.

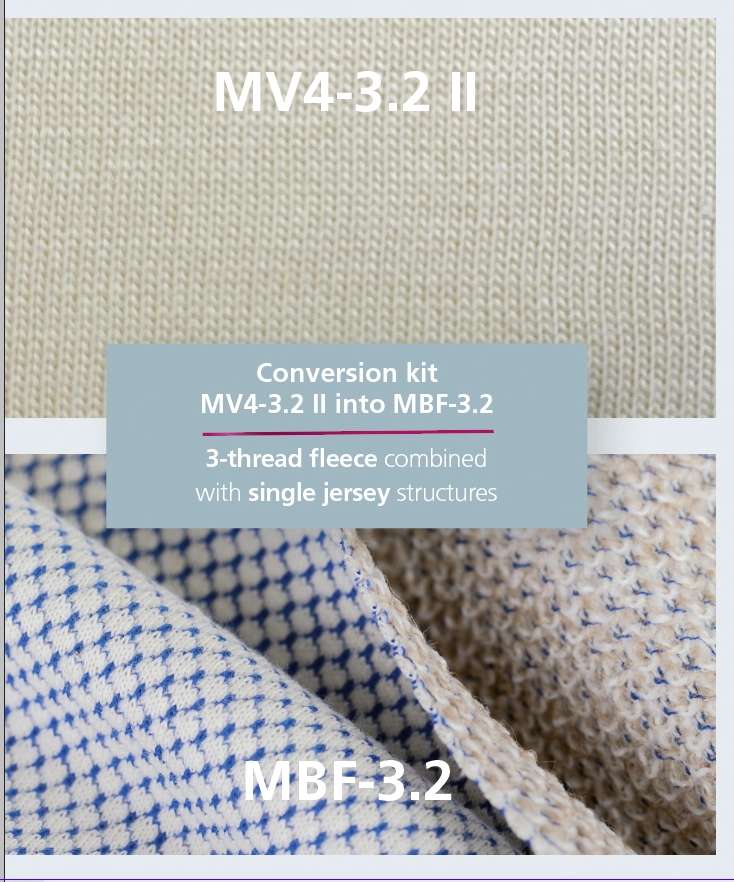

Make your single jersey star fit for producing 3-tread fleece..

Control 5.0.

New, state-of-the-art machine control.

Required for using knitlink digital service cloud.

Meet today‘s demand in 3-thread fleece combined with single jersey structures.

Plaiting the fabric with the Mayer & Cie. folding device combined with our swing box is sensible for tubular fabrics made of delicate or elastomeric yarns.

A good match: Folding device and special take down

Increase machine output for elastomeric plating knitted fabrics by up to 30 percent. Compatible with the following machine types: Relanit 3.2 II, Relanit 3.2 S..

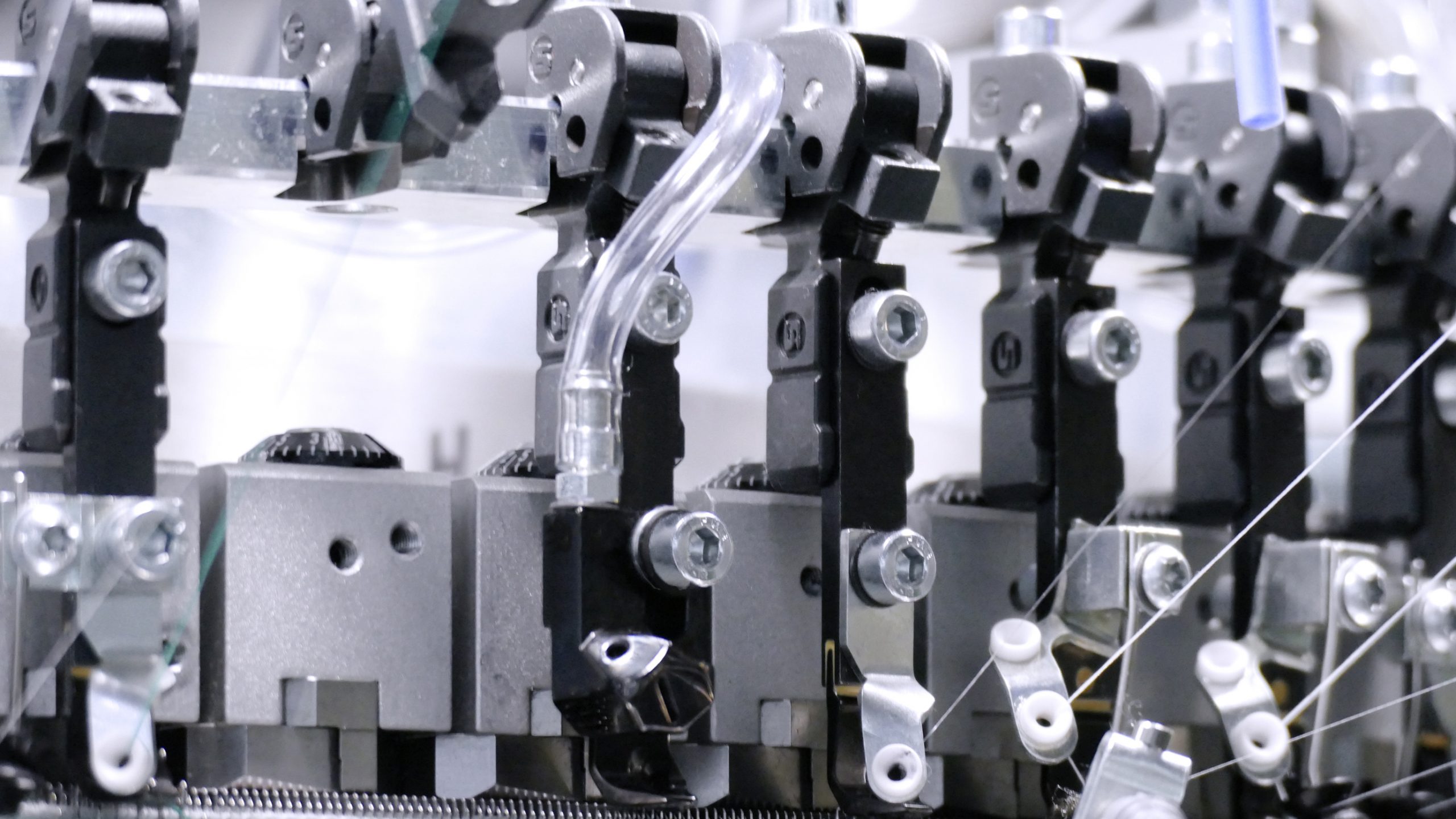

Blow clearing of fluff during knitting process

Particularly recommended for all spun yarns.

Control 5.0 ist die neue Maschinensteuerung der Mayer & Cie.-Maschinen. Sie ist Voraussetzung für den Einsatz der knitlink-Applikationen. Ab 2024 wird sie serienmäßig in allen Rundstrickmaschinen verbaut. Für Maschinen ab Baujahr 2001 ist Control 5.0 als Upgrade erhältlich, entweder in der Standardausführung als SmartControl oder als ClassicControl.

knitlink ist das Web-basierte Kunden und Maschinenportal von Mayer & Cie. Es ist das Hub für alle Informationen sowie Services rund um die Rundstrickmaschine. Derzeit verfügt knitlink über drei Komponenten: my.monitoring, my.shop und my.services. einen schwerwiegenden oder wiederkehrenden Fehler, wird die Maschine gestoppt.

knithawk ist ein Tool zur optischen Fehlererkennung. Es sitzt direkt hinter der Strickstelle und besteht aus einer Kameraeinheit, die das Gestrick mittels Infrarotlicht „abscannt“. Erkennt knithawk einen schwerwiegenden oder wiederkehrenden Fehler, wird die Maschine gestoppt.

Technical data:

Diameter [inch]: 26″ – 38″

Machine gauges [E]: 14 – 32

No. of feeders: 66 at 30″

Speed up to [rpm]: 38 rpm at 30″

Speed factor (SF): 1140

Mayer & Cie. GmbH & Co. KG

Emil-Mayer-Strasse 10

72461 ALBSTADT

GERMANY

Postadresse:

Postfach 201580

72438 ALBSTADT

GERMANY

Tel. +49 (0)7432 700-0

Fax +49 (0)7432 700-362

info(at)Mayercie.com

Bewerbungen über unser Karriereportal